|

How Digi-Arc Supports Manufacturing and Service Needs on the Factory Floor

|

1. Enabling Real-Time Data Collection & Analytics

Edge Devices & IIoT Integration:

- Digi-Arc designs architectures that connect factory assets (PLCs, sensors, machines) to IIoT platforms.

- Use edge computing to process data locally, reducing latency and enabling real-time insights.

Data Pipelines & Visualization:

- Implement data pipelines that extract, transform, and load (ETL) shop floor data into centralized data lakes or cloud platforms.

- Enable real-time dashboards and visualizations using Power BI, Tableau, or Grafana.

Predictive Maintenance & Anomaly Detection:

- Leverage machine learning algorithms to predict equipment failures and optimize maintenance schedules.

- Use anomaly detection techniques to identify deviations in production quality.

Example:

On a pharma factory floor, real-time monitoring of temperature, humidity, and batch deviations ensures compliance with GMP standards.

|

|

|

2. Driving Digital Manufacturing with MES & ERP Integration

MES (Manufacturing Execution System) Integration:

- Digi-Arc designs solutions that connect MES with ERP systems (SAP, Oracle) and warehouse systems (WES/eWM) for synchronized production planning.

- Enable real-time work-in-progress (WIP) tracking and automated production scheduling.

Low-Code/No-Code Platforms for Shop Floor Apps:

- Use platforms like Tulip, Plex, or Siemens Mendix to build custom apps for operators and supervisors.

- Apps streamline tasks such as quality checks, maintenance logging, and downtime reporting.

ERP-Driven Material Management:

- Real-time inventory and material flow visibility using ERP integration reduces downtime and optimizes production planning.

Example:

In a discrete manufacturing plant, MES-ERP integration ensures real-time production scheduling and automated lot tracking.

|

|

|

3. Smart Maintenance & Asset Management

Digital Twins for Asset Monitoring:

- Architects build digital twins of production lines or critical assets, simulating operations and predicting potential failures.

- Use IoT data streams to keep the twin synchronized with physical equipment.

Connected Maintenance Workflows:

- Integrate CMMS (Computerized Maintenance Management Systems) with MES and ERP.

- Automate maintenance work orders based on real-time asset conditions (e.g., vibration thresholds or thermal anomalies).

Example:

In an automotive plant, vibration sensors on stamping machines trigger automated service tickets when thresholds are exceeded.

|

|

|

4. Enhancing Service with AR/VR & Remote Assistance

Augmented Reality (AR) for Field Service:

- Digi-Arc designs AR solutions for remote diagnostics and guided maintenance.

- Field technicians use HoloLens or mobile AR apps to access real-time service manuals, schematics, and expert assistance.

Remote Monitoring & Service Portals:

- Deploy customer portals for service visibility, allowing clients to track asset conditions, request services, and monitor SLAs.

IoT-Powered Service Models:

- Architects enable IoT-powered predictive service models, reducing unplanned downtime through remote monitoring and preemptive part shipments.

Example:

In an industrial equipment plant, AR-guided maintenance reduces service times by 30%.

|

|

|

5. Cloud & Edge Integration for Scalable Solutions

Cloud-Native Architectures:

- Design scalable platforms on AWS, Azure, or Google Cloud to store and process large volumes of factory data.

- Use API gateways and microservices for seamless integration with existing systems.

Edge Computing for Low-Latency Needs:

- Deploy edge devices to process machine data locally, reducing the need for constant cloud connectivity.

- Use MQTT or OPC UA protocols to stream relevant data to cloud platforms for further analysis.

Example:

In a pharmaceutical factory, edge devices process GMP-compliant sensor data locally to prevent latency issues.

|

|

|

6. Cybersecurity & Compliance

Secure Factory Networks:

- Digi-Arc implements zero-trust architectures to protect OT and IT networks.

- Use role-based access control (RBAC) and network segmentation to prevent unauthorized access.

Compliance with Industry Standards:

- Ensure systems align with ISO 27001, NIST, and GxP requirements.

- Regular audit trails and logs for compliance verification.

Example:

In a medical device plant, adherence to 21 CFR Part 11 ensures secure data logging and traceability.

|

|

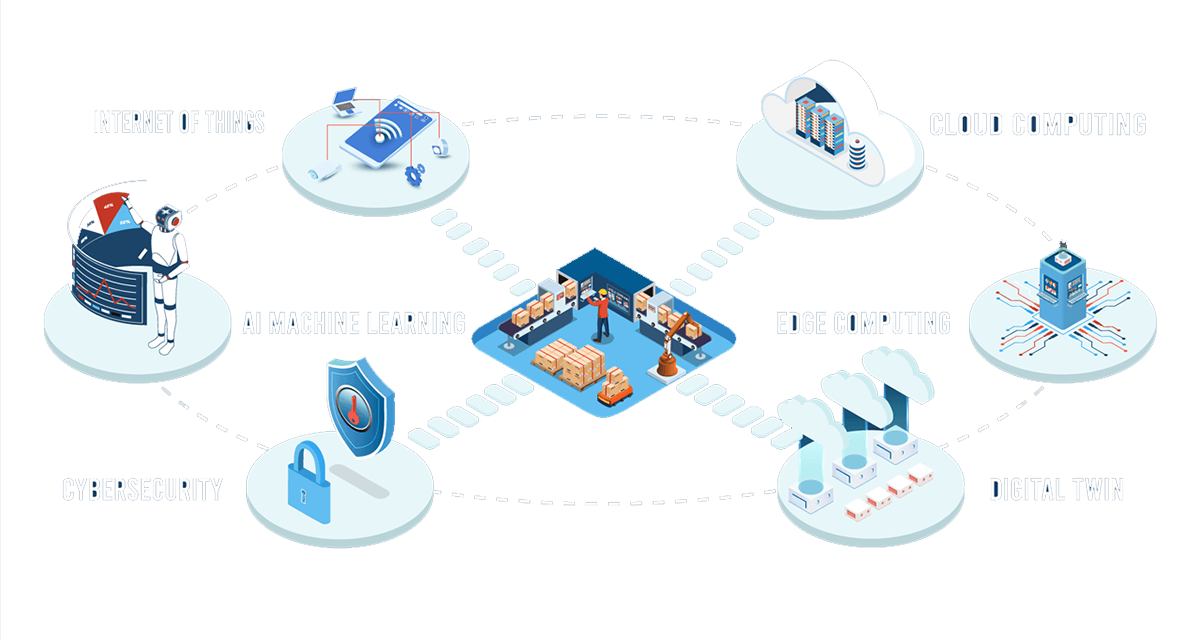

Key Technologies Involved

- Platforms: Tulip, Siemens MindSphere, AWS IoT, Azure IoT, Google Cloud IoT

- Protocols: MQTT, OPC UA, REST APIs

- Data & Analytics: Power BI, Snowflake, Grafana, Databricks

- Edge & Cloud: Azure Stack Edge, AWS Greengrass, Google Distributed Cloud

- AR/VR Tools: Microsoft HoloLens, PTC Vuforia, TeamViewer Frontline

Impact of Digi-Arc on the Factory Floor

- Improved Operational Efficiency: Real-time insights reduce downtime and optimize production.

- Enhanced Quality Control: Automated anomaly detection and traceability boost compliance.

- Streamlined Service Operations: Remote monitoring and AR-powered service improve response times.

- Scalable & Future-Proof: Cloud-native and edge architectures ensure scalability.

|